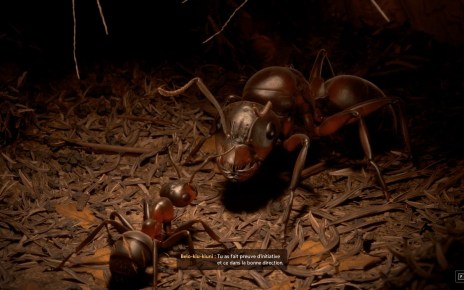

We review Empire of the Ants, an RTS where you control armies of ants to defeat enemies such as termites or black ants, while exploring environments in a lush forest.

Author: Fabrice Stellaire

Square Enix Producer Asks Star Ocean Fans to be Patient

You will have to wait before playing Star Ocean 6

Metro Exodus is delayed to Q1 2019

You will have to wait one more year before exploring the underground of Metro Exodus.

Beyblade Burst: Battle Zero is coming to Switch

Get ready to spin with this upcoming new Beyblade game!

Platinum Games Teases a New Action Game

Several Games are being developed by Bayonetta’s developer!

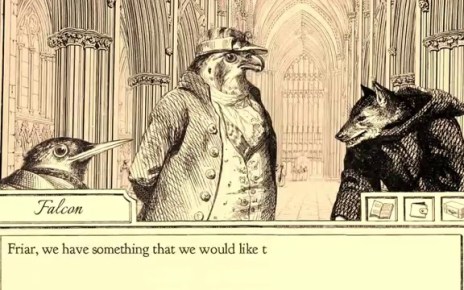

REVIEW: Aviary Attorney

Even birds can be attorneys in this game set in Paris during the 19th century.

IMPRESSIONS: Prismata

A virus has infected robots, and you have to defeat them with cards.

PAX East 2018: Square Enix Lineup and Events

The first-ever North American FINAL FANTASY Trading Card Game (“FFTCG”) Crystal Cup tournament will also take place.

Square Enix creates a new Studio lead by Hajime Tabata

A new studio comes, with new projects and dreams.

Masters of Anima will launch on April 10

Command an army of magical Guardians to defeat Zahr and finally rescue your bride in this adventure-strategy game!

REVIEW: Overgrowth

Can a rabbit defeat cats, dogs and wolves? Let us find out with Overgrowth.

Kirby Star Allies gets new Dream Friends

Kirby always looks for new friends in his adventures.

Assault Gunners HD Edition gets a Japanese Trailer

The remastered edition of Assault Gunners gets new videos!

Cursed Castilla and Super Hydorah Headed to Switch

Face challenging adventures in space and in medieval Spain on the Switch!

Bandai Namco Announces Game Based on Record of Grancrest War

The famous light novel series gets a video game!

Capcom has Shipped Over 7.5 Million units of Monster Hunter World

The latest Monster Hunter game hits a new milestone

Secret of Mana Getting a Major Update in March for PS4

Secret of Mana is getting an important update that fixes major bugs.

Visual Novel Root Letter sold over 400 000 units.

Root Letter has sold over 400 000 units, thanks to an intriguing story.

Hokuto ga Gotoku Gets Two Gameplay Explanation Videos

The Wasteland has never been more entertaining! Explore the desert and entertain yourself in the city of Eden in those new videos.

Valkyria Chronicles 4 gets a new Federation Army trailer

Learn more about the protagonists of Valkyria Chronicles 4 in this new trailer!